Hohenstein Testing and Analysis

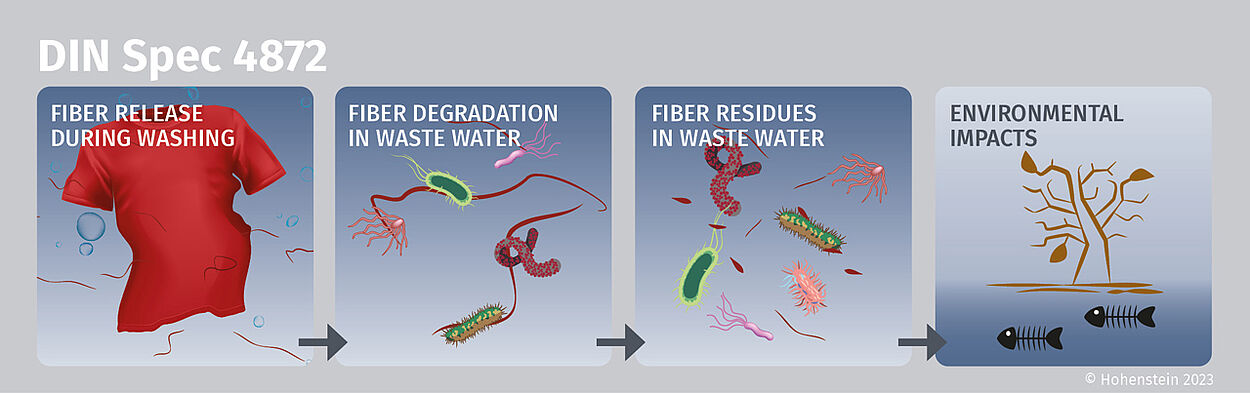

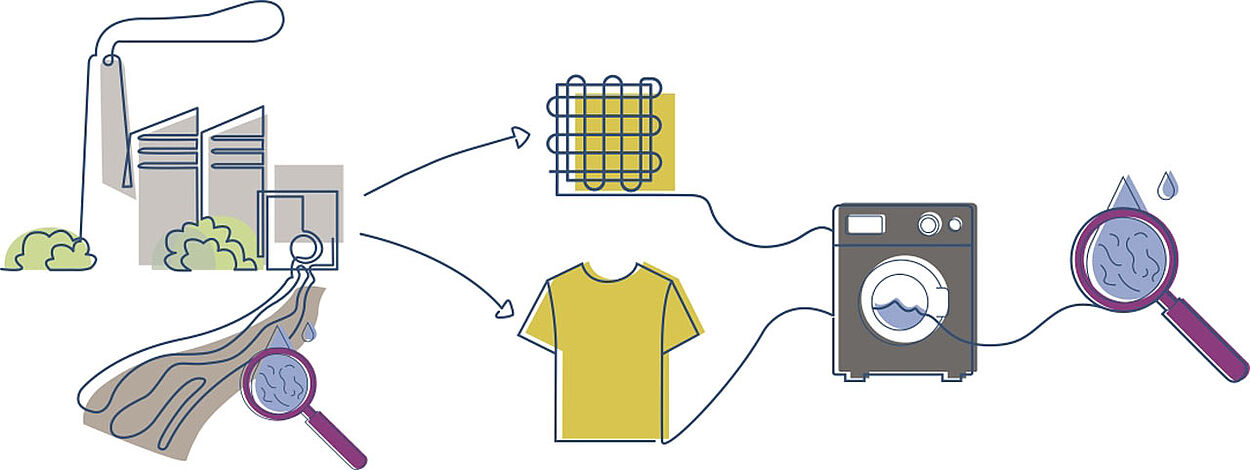

- Classification of the fiber discharge during the washing process

- Verification of the fiber residue's biodegradability in wastewater (DIN EN ISO 14851) and the degree of degradation within a defined period of time

- Determination of the ecotoxicology of the fiber residues (DIN EN ISO 20079) after the biodegradation process